to design, build or mount

-

Warehouse and logistics complexes

-

Shopping and entertainment centers

-

Motor shows, car wash and service stations, refueling complexes

-

Trade and exhibition pavilions

-

Production halls and buildings

-

Agricultural constructions

- Buildings of cattle farms

- Feed mills

- warehouses, awnings and hangars

- Vegetable stores

- cold storage buildings

will offer you the best option

STEEL QUICK-REPAIRABLE LONG-TERM

AND ENERGY EFFICIENT BUILDINGS

Profiled sheeting

(For cold buildings)Frames of the frame

(Additional elements)Metal carcass

From black or galvanized profilesRoofing

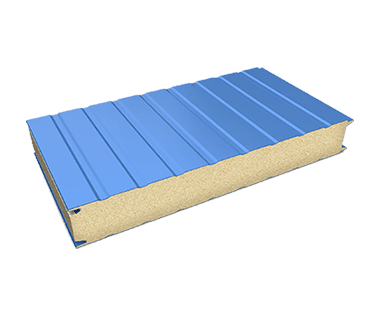

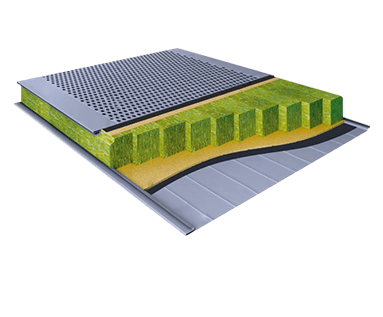

Panels

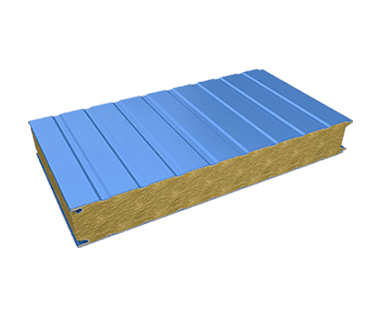

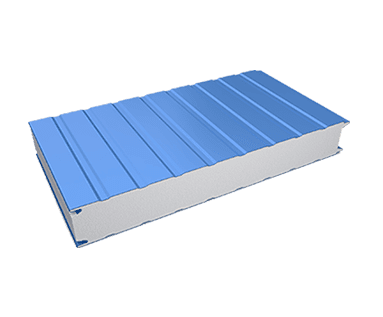

Wall panels

(For warm buildings)Nodes

On bolted connectionsmade of lightweight galvanized profiles

by 2 times

foundation

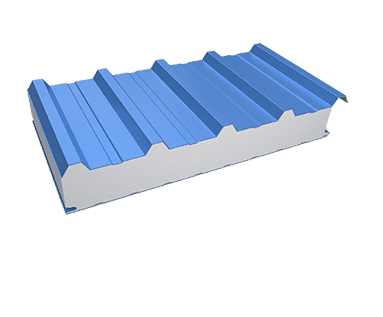

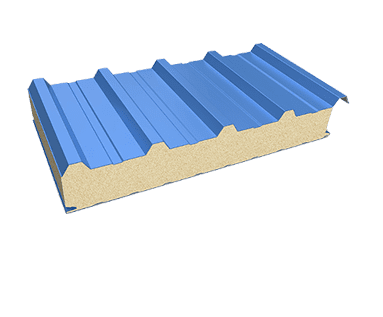

SANDWICH-PANELS of own production

elements

elements

elements

elements

elements

elements

EI 60, EI 120, EI 150

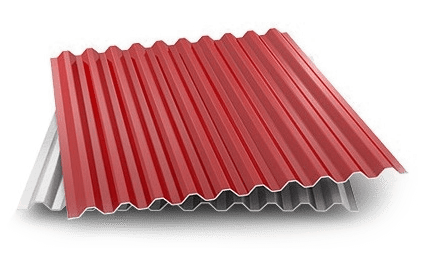

Professional flooring of our own production

- Reliable operation of the structure with a large temperature range (from -52 ° C to + 63 ° C)

- Construction in a short time (2-4 months), the ability to work at any time of year

- Excellent heat-saving characteristics of BMZ, high acoustics

- A decent aesthetic appearance of the facade of the structures - without additional finishing.

- Average service life of the facility is about 26 years

we will take care of yourself!

Contact us right now and we will make an offer,

From which you can not refuse!

-

supply

+38 (0512) 58 74 54 -

marketing

+38 (050) 337 14 80

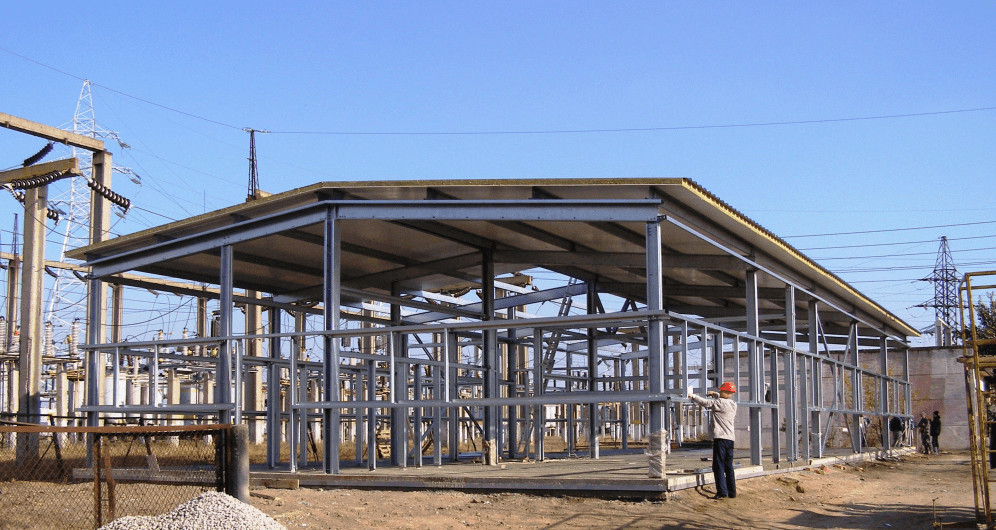

Prefabricated buildings

Promstan Corporation began its work in 1997, having passed the path from a small enterprise to a large authoritative company, which occupies a leading position in its segment of the Ukrainian construction market.

The main activities:

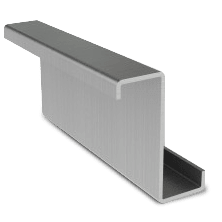

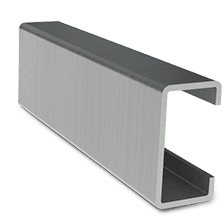

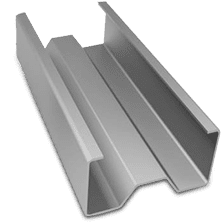

- Design, installation of BMZ, production of zinc-plated profiles of type Z and C, design and manufacture of rolling equipment, profiles for greenhouses;

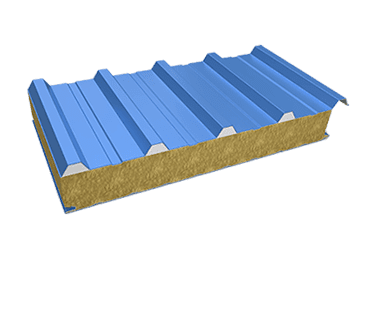

- Production of wall and roof sandwich panels with mineral wool filler (Rockwool, Danova) Density of 115 kg / m 3 and expanded polystyrene, as well as components to them;

- Production of corrugated board and bent profiles to it;

- General construction works, manufacturing and installation of metal structures, all types of excavation and reclamation, earth-moving equipment, lifting equipment, vehicles, repair of all types of construction equipment.

Today, Promstan Corporation includes several large enterprises that unite a wide range of production areas and are able to successfully implement even the most complex projects. Priority areas at the moment are: the production of sandwich panels and the manufacture of prefabricated buildings, from design to the delivery of the finished object.

а

-

Depending on the building area, the construction of prefabricated buildings is carried out within two to four months. At the same time, the presence of qualified teams, our own special equipment and the ability to carry out work at any time of the year allow our company to guarantee strict adherence to all the agreed terms of construction.

-

The cost of building prefabricated buildings depends on their type and ranges from 1200 hryvnia per square meter for arched BMZ to 4500-6500 hryvnia / sq. m for buildings based on welded metal structures. Our price is the most favorable on the Ukrainian market, and compliance with all technological standards guarantees the reliability, safety and durability of the erected structures.

-

Thanks to the use of high-quality materials protected from atmospheric factors, the average service life of prefabricated buildings in a changeable climate in the temperate zone is about 25 years. At the same time, the excellent maintainability of BMZ allows to significantly increase the term of their use.