Installation of sandwich panels

The strength of quick-erect structures depends on the correct installation work.

The installation of sandwich panels does not cause any particular difficulties, but should be carried out by specialists.

The quality of installation depends not only on the quality of the sandwich panels,

but also on the fastening materials, equipment and tools used.

Why we are chosen?

intermediaries

of sandwich panels

Our competitive advantages are the following:

- The design department of the company will lay out the sandwich panels for FREE!

- Experienced high-riggers carry out installation of sandwich panels all year round;

- 150m2 per shift - the average speed of installation by a team of 5 people;

- We pay special attention to the correct installation procedure using high-quality components.

You no longer need to look for anyone and overpay

- we will take care of your worries!

We manufacture and install

Sealing non-hardening double-sided tape coated with a protective siliconized layer.The tape is used for gluing rolled roofing and waterproofing materials

Universal foam triangulated seal. The length is 1 m. Prevents clogging of snow under the metal tile in the places of installation of ornamental strips.

Specialists of the company use silicone sealant to seal joints and seams in the construction of FTB

Head - hexagon with collar, 8 mm turnkey. Washer - with a flat gasket EPDM. Head - hexagon with collar, 8 mm turnkey. Washer - with a flat gasket EPDM Thread - under the head 6.3 mm sparse, main - 5.5 mm with a cutting groove, frequent. Tip - a drill with a notch in the thread. Coating - white zinc

Sealing waterproofing tape is a material on a foamed polymer base, covered with glue on one side. It is used as an insulation of the junction points of the counter rail to the hydrobarrier (film or membrane).

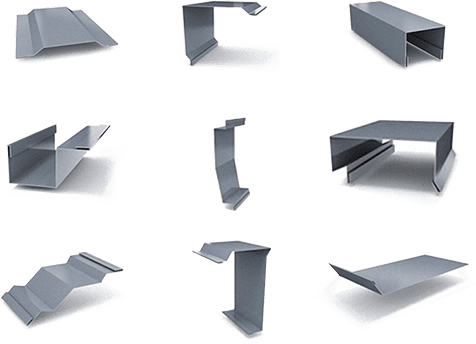

Special slats are designed to provide structures with greater reliability and functionality, as well as help protect structures from moisture, dust, debris and dirt, give it a finished and aesthetic look.

Non-standard precast components are used for partitions, joints and abutments of enclosing structures, parapets, cornices, window blocks, etc For the roof - these are roof ridge, roof valleys, wind and connecting splats. For facades - outer and inner corners, front, upper and lower slats, as well as side slats for windows, parapet, plinth and transition elements.

What affects the cost of installing sandwich panels?

- The cost depends on many factors: the height of the fastening, the complexity of the access roads, the number of joints and fasteners.

- The availability of highly qualified personnel and modern equipment allows our corporation to guarantee the completion of any amounts within the time period stipulated by the contract.

- Installation of sandwich panels can be carried out in horizontal and vertical versions, each of which has its own features.

- To ensure a reliable connection, it is required to calculate the pitch of fastening of the products with self-tappingscrews to the metal frame.

- The most profitable order from the point of view of cost savings is the order of turnkey construction. In this case, many of the nuances will be taken into account by our engineers at the design stage, the cost of installing sandwich panels will be minimal.

- We know how to build quickly and reliably! Contact us - see for yourself!

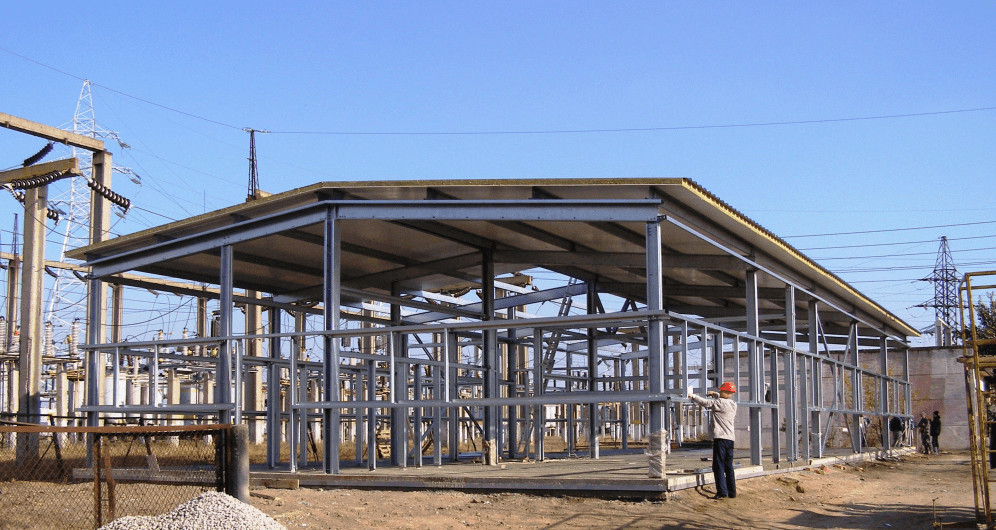

Practical quick-erected buildings (QEB), in essence, are a metal frame, sheathed with sandwich panels. The quality of such structures depends on the materials used and the correct assembly of structural elements. The price for the installation of sandwich panels is made up of the size of the sheathed area and the required density of fastenings.

Practical quick-erected buildings (QEB), in essence, are a metal frame, sheathed with sandwich panels. The quality of such structures depends on the materials used and the correct assembly of structural elements. The price for the installation of sandwich panels is made up of the size of the sheathed area and the required density of fastenings.

Promstan Corporation is a manufacturing plant of components for QEB, producing metal frames, sandwich panels and profiled sheeting using the most modern technologies for the construction of structures of any size. In addition to production, we carry out all types of installation work with similar products. It is not difficult to order both the sandwich panels themselves and their installation from us. A free quick cost estimation for your order can be requested directly from this website.

Service features

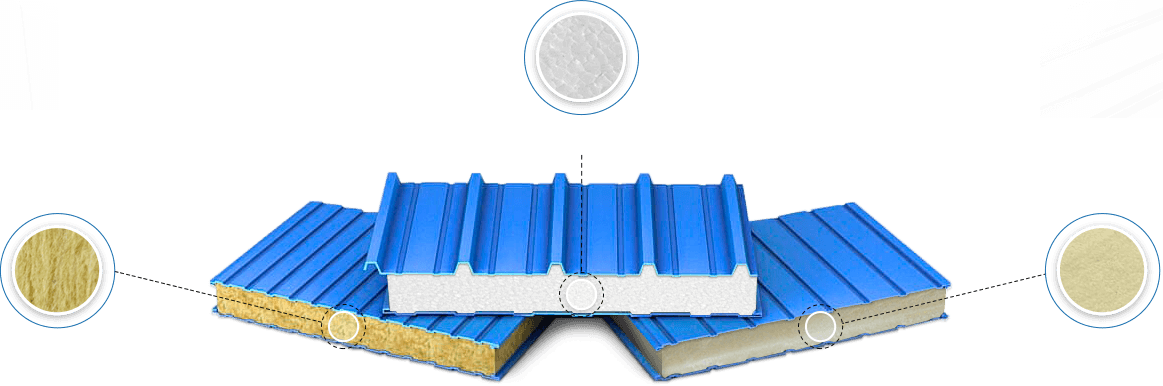

Sandwich panels with mineral wool and expanded polystyrene insulation are an excellent modern building material that has many advantages which are already highly appreciated in our country. Ease of installation on a metal frame using self-tapping screws allows to erect walls and roofs of buildings in a short time.

To get a high-quality installation of a sandwich panel, the price for the work cannot be low.

Panel mounting procedure consists of the following main stages:

- preparatory work;

- installation and fastening with self-tapping screws;

- sealing joints;

- installation of finishing accessories (weather strips).

At each stage, there are nuances in the work, on which the durability of the structure largely depends. At the preparatory stage, when cutting the panels, it is important not to disturb the coating layer and the mechanical integrity of the product, therefore, it is necessary to use special tools and lifting devices. Installation can be carried out in horizontal or vertical versions, each of which has its own features. To ensure a reliable connection, it is required to calculate the pitch of fastening of the products with self-tapping screws to the metal frame.

Cost of work

We manufacture and install products for both wall and roofing purposes. How much does sandwich panel installation cost? It depends on many factors: the height of the attachment, the installation position of the products, the number of joints and fasteners. The availability of highly qualified personnel and modern equipment allows our corporation to guarantee the completion of any amounts within the time period stipulated by the contract.

The most profitable order from the point of view of cost savings is the order of QEB turnkey construction. In this case, many of the nuances will be taken into account by our engineers at the design stage, the cost of installing sandwich panels will be minimal. We know how to build quickly and reliably!

We also offer to use the service:

-

The average speed of installation of sandwich panels is about 150 square meters per one working shift of a team of five people, which makes it possible to erect medium-sized one- and two-story buildings within one to one and a half months. The company "Promstan" carries out complex construction of buildings from sandwich panels in a short time frame.

-

The average cost of installing sandwich panels ranges from 200 to 270 hryvnia per square meter. In this case, the final price of installation work depends on a number of factors, including the height of the building and the number of components, the required construction time and other conditions. The experts of the Promstan company carry out the installation of panels promptly and in compliance with all standards.

-

Performing a full range of works on the production, delivery and installation of sandwich panels, the Promstan company provides its customers with all the necessary components: from self-tapping screws to seals and sealants. During installation, exclusively reliable components and additional elements are used.