Laser cutting of metal

This is one of the most modern, efficient, high-precision and cost-effective methods of nesting and cutting various metals: steel, brass, cast iron, aluminium, stainless steel.

Laser cutting technology provides high quality and accuracy of the product, high productivity, reduces the amount of consumables, production time, allows the production of parts with a complex geometric boundaries, with high precision to comply with the requirements of the drawings.

without intermediaries

facilities 4000 m²

for metal laser cutting services

| cutting precision | 0,1 mm |

| laser power | 4 кВт |

| operational range | 3000*1500 mm |

| maximum sheet weight | 800 kg |

| control system | ЧПУ Siemens |

*the value of the parameters may vary depending on the wishes of the Customer.

Steel

up to 20 mm

Stainless steel

up to 15 mm

Aluminium alloys

up 10 mm

Non-ferrous metals

up 10 mm

and are ready to offer the best prices on the market.

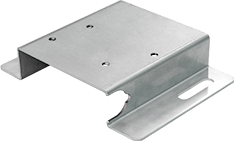

Elements

Elements Tools

Tools Tools

Tools Bench

Bench Balconies

Balconies Gates

Gates

Advantages of laser nesting of metal:

- lack of mechanical contact allows processing fragile and easily deformable materials;

- materials from hard alloys are processed;

- high-speed cutting of thin sheet steel is possible;

- when producing small batches of products, it is more expedient to carry out laser nesting of the material than to manufacture expensive moulds or casting forms for this;

- for automatic cutting of the material, it is enough to prepare a drawing file in any drawing program and transfer the file file to the machine CNC.

You no longer need to look for anyone and overpay -

will take care of your worries!

Low carbon steel (Ferrous metal)

| Metal sheet, mm | Рrice 1 m/r | Price of 1 punching |

| 0,5-1mm | 11 UAH | 4 UAH |

| 1.5-2mm | 13 UAH | 4 UAH |

| 3mm | 16 UAH | 4 UAH |

| 4mm | 20 UAH | 6 UAH |

| 5mm | 22 UAH | 6 UAH |

| 6mm | 25 UAH | 6 UAH |

| 8mm | 33.5 UAH | 8 UAH |

| 10mm | 44 UAH | 9 UAH |

| 12mm | 55 UAH | 10.5 UAH |

| 14mm | 65.5 UAH | 13 UAH |

| 16mm | 76 UAH | 14,5 UAH |

| 18mm | 92 UAH | 16.5 UAH |

| 20mm | 108 UAH | 18.5 UAH |

| Metal sheet, mm | Рrice 1 m/r | Цrice of 1 punching |

| 0,5-1-2mm | 23 UAH | 4 UAH |

| 3-4mm | 30 UAH | 5 UAH |

| 5-6mm | 36 UAH | 6.5 UAH |

| 7-8mm | 50 UAH | 8 UAH |

| 9-10mm | 72 UAH | 10.5 UAH |

| 11-15mm | 104 UAH | 14 UAH |

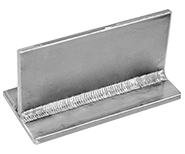

Bending of a metal sheet allows to make products and parts of varying degrees of complexity and configuration, as well as non-standard designs. The main process advantage of this method is that it allows the production of monolithic metal products completely without welds. This has a positive effect on their strength, corrosion resistance and durability.

| Bendable metal thickness | FROM 0.5 TO 10 mm |

| Maximum bending length | 4000 mm |

| Beam stroke height | 500 mm |

| Number of matrix positions | 2 |

| Auxiliary lifting device | CNC |

| Digital bend gauge | 2 pieces |

| Tolerances | +/- 1 grade |

*the value of the parameters may vary, depending on the wishes of the customer.

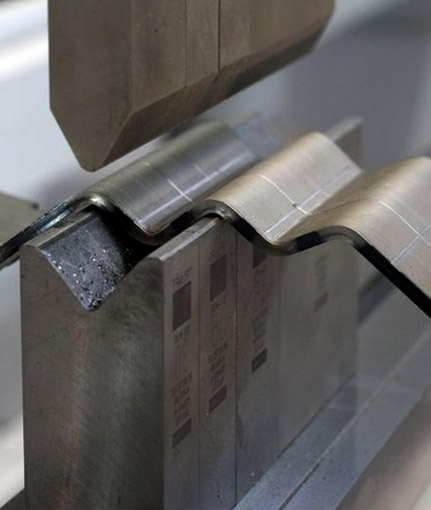

Metal sheet laser cutting - quality and speed of work

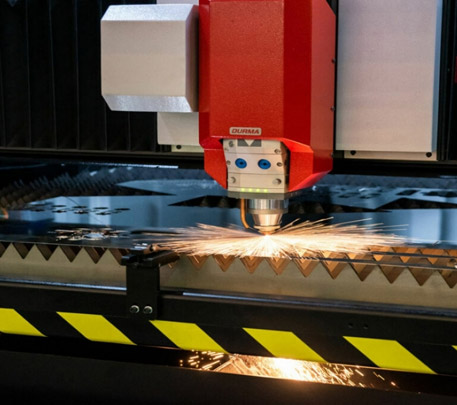

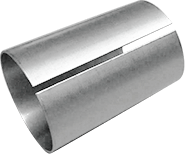

Laser cutting of metal is used for non-standard and shape nesting of sheet aluminium, steel and other materials. The result of the work is a neat part with an even cut edge (no scale), exactly corresponding to the dimensions in the design documentation. Promstan Plant provides services for laser curvilinear metal cutting. Shape and decorative nesting is done in any shape, without restrictions. The corporation's assets include modern equipment (CNC machines of the German model Trumpf TruLaser 3030).

Technology capabilities

The most complex boundaries are cut with a laser and thereby bring to life any design ideas from a metal sheet. This technology allows to:

- process different materials. The Promstan Plant performs laser nesting of sheets of stainless steel, aluminium, non-ferrous and ferrous metals (cast iron, etc.). In addition, the CNC machine can process not only hard alloys, but also brittle materials. The laser affects only the required areas, therefore, during the cutting process, the sheets are not deformed, since they do not experience mechanical stress;

- to obtain mirror-smooth cutting edges (without microburrs). In most cases, the part does not need further finishing and end-face processing;

- to produce elements with complex geometrical boundaries and fancy patterns according to the customer's sizes. All processes are automated and computerized, due to which errors and defects are eliminated. The equipment can handle sheets with dimensions of 3,000 x 1,500 mm and a maximum weight of up to 800 kg. The finished part corresponds to the dimensions in the drawings. Cutting accuracy - 0.1 mm;

- carry out high-speed nesting of sheet steel. Equipment power - 4 kW;

-

reduce the amount of consumables. Non-contact cutting provides precise lines, angles, holes. Efficient nesting of aluminium, steel or cast iron alloy minimizes waste, which is beneficial for any business in Ukraine.

Important! In the production of a small batch of products, it is better to order nesting of a metal sheet with a laser, and not to manufacture expensive casting forms or moulds specially for this.

Factors determining the cost of the service

The price for laser nesting of metal depends on:

- physical and chemical properties of the material;

- sheet thickness. The maximum material thickness that the laser can process: non-ferrous metals - up to 10 mm, steel - up to 20 mm, stainless steel - up to 15 mm, aluminium alloy - up to 10 mm;

- applied technology. Sheet metal nesting is performed in oxygen or nitrogen. In the first case, a high speed of operation at low pressure is provided. Material laser cutting with the oxygen is inexpensive compared to nitrogen technology. The latter is used for machining alloys that do not tolerate oxidation. The method allows to perform complex boundaries and shapes under high pressure conditions;

- urgency of customised laser cutting metal;

-

features of the required pattern (determines the complexity of programming for setting up the machine).

The cost of work is calculated per square meter.

Unified approach

The Promstan Plant is an integrated works enterprise. We offer to order services in the following range:

- laser cutting of sheet metal;

- material bending. The method allows the production of monolithic metal products completely without welded seams;

- drilling holes;

- welding works;

- rolling on mills.

For automatic nesting of the material, it is enough to prepare a drawing file and transfer it to the CNC-machine program. Promstan Corporation fulfills orders in Nikolaev and Kherson.

-

This technology is used for processing conventional and stainless steel with a thickness of up to 20 and 15 millimeters, respectively. It is also used to cut aluminum alloys and other non-ferrous metals up to 10 mm thick. In the Promstan company you can order high-precision laser cutting of these materials.

-

The cost of laser cutting depends on the type and thickness of the material, it ranges from 11 to 110 hryvnia per linear meter. In addition, the price is influenced by such factors as the volume of processed products, the geometry of the required products, as well as the desired timing of the work. The Promstan company offers the most optimal prices for laser cutting of metals on the Ukrainian market.

-

Our company for the process of laser cutting of metals uses modern German equipment with programmable control systems from the TRUMPF trademark. This allows you to ensure the accuracy of the cut with an error of no more than 0.1 millimeter, as well as to carry out large volumes of material processing in a short time.